Beverage / Isobaric / Beer Bottle Filling Machine

- Mobile: +86 15850399126

- Email: bella@jinrifillingmachine.com.cn

Beverage / Isobaric / Beer Bottle Filling Machine

DYGF12-1 Beer can filling and sealing machine is used in aluminum can, tinplate can, and also widely used in beer, beverage drink, isobaric filling machine. The whole process is depalletizer machine→beer can rinsing machine→beer can filling and sealing machine→beer pasteurizer tunnel machine→dryer machine→shrink sleeve labeling machine/sticker labeling machine→inverted can→date printer machine→Film wrapping machine/carton packing machine.

This machine is the introduction of German filling sealing technology, after digestion and absorption, the design and manufacture of cans filling sealing equipment can be widely used in carbonated beverage, such as beer cans filling and sealing. It is widely used in aluminum cans, tin cans, stable equipment performance, advanced technology, beautiful shape, fully functional. Beer factory, the first choice of small craft breweries use.

Filling machine is the introduction of German technology, the use of isobaric filling technology to design and manufacture, the liquid filling to achieve good washing jars. Isobaric filling valve using mechanical valve design uses three open valve and twice closing valve, by increasing the switching valve means to control the amount of oxygen in beer, while ensuring that sensitive filling fast, filling high-level precision.

Adopt filling valve orifice with guide means combined to ensure accurate sealed bottle and filling valve, reducing the material from can mouths leakage phenomenon.

Depending on the height of the can type, it can automatically lift to meet the filling requirements. Dial positioning plate designed to adjust the bottle type single-station standalone, single-position adjustment can be adjusted without affecting other stations.

Gear transmission has high efficiency, low noise, long life, easy maintenance, lubrication fully, the frequency control the main motor speed , machine adopts stepless frequency control.

Bottle guide system is simple,it can be quickly and easily changed according to the cans type, the machine use the whole can bottom structure supported.

It uses PLC automatic control, easy to operate, a fault-line display. With no cans valve does not open, no add caps, lack of cover downtime and other security features.

Filling cylinder's material automatic control, using highly liquid level sensor testing to ensure reliable filling level and stable.

With perfect CIP cleaning function, you need to configure CIP cleaning machine can achieve a comprehensive hydraulic cylinder and pipe cleaning. Each filling valve has cleaning cup, more convenient cleaning.

Sealing machine seal the lid on the jar filled already good product, sent by the conveyor after the procedure. Cans roller with high hardness alloy steel hardened, sealing curve optical curve grinding precision machining, to ensure the sealing quality, to ensure the normal operation of the machine.

This machine has a can having a cover, no cans no caps control system, in order to ensure the normal operation of the machine, reducing the rate of loss cover.

Artificial aluminum lid placed in the chute by gravity and thruster cover next cover, fitted in the chute detection switch for lack of guarantee cover will automatically stop.

Depending on the different cans height , sealing machine can automatically lift to meet the requirements.

| Capacity | 1000-1500cans/hour |

| Filling product | beer cans |

| Filling head | 12head (filling valve use nanjing valve) |

| Sealing head | 1pcs |

| Suitable can height | 90~150mm |

| Suitable can diameter | ф50~ф70mm |

| Filling pressure | 0.3-0.5Mpa |

| C02contain | 8g/m3 |

| C02pressure | 0.5-0.6Mpa |

| Motor power | 2.5KW |

| Working voltage | 380V |

| Size | 2150×1600×2250mm |

| Weight | 3000Kg |

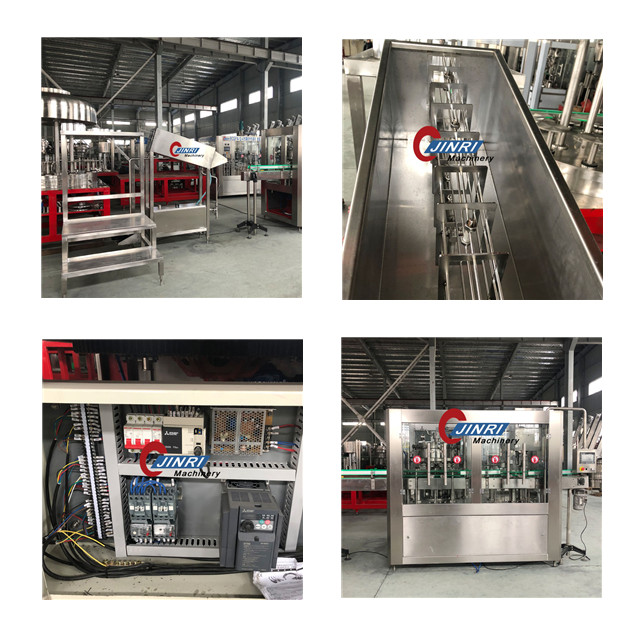

BGF12-1 Beer can filling and sealing machine photo details:

By continuing to use the site you agree to our privacy policy.