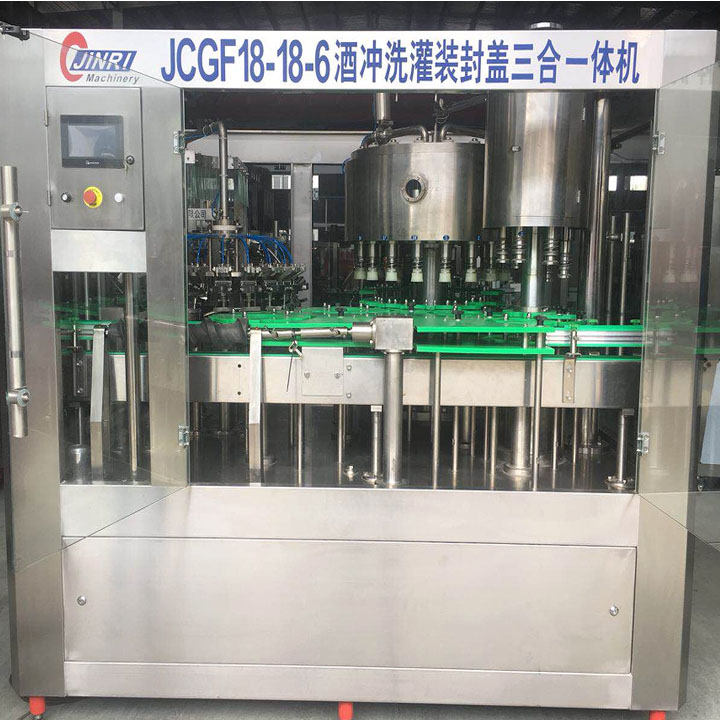

Beverage / Isobaric / Beer Bottle Filling Machine

- Mobile: +86 15850399126

- Email: bella@jinrifillingmachine.com.cn

Beverage / Isobaric / Beer Bottle Filling Machine

This machine integrates the flushing filling gland into one, mainly used for the flushing and filling of glass bottles and the rolling cap of aluminum anti-theft cover. It is suitable for the filling of non-aerated beverages such as water and alcohol. It has the characteristics of good sealing quality, compact structure, low noise and convenient operation and maintenance.

★ machine frame

The structural steel body has a 304 stainless steel layer, a 304 stainless steel frame and a stainless steel adjustable foot.

★ belt conveyor system

It is conveyed by the bottom of the bottle, and the conveying is stable. The stainless steel conveyor chain, the oil nylon wheel and the guide plate.

★ rotary type washing machine

The number of bottle holders is 18, and the snap-in bottle holder clamps the bottle mouth and the bottle body at the same time, ensuring that the glass bottle can be freely turned over. The rinsing nozzle is a solid conical nozzle that can be flushed to the wall and bottom of the bottle to make the rinsing cleaner.

The rinsing head can be adjusted to accommodate bottles of different heights.

★ rotary type filling head

The number of filling valves is 18 and the micro-negative pressure filling technology is adopted. There is no dripping phenomenon, and the liquid level error is less than 5mm.

The use of mechanical bottle lifting device lift bottle can limit the height error between glass bottles. And there is a pre-covering device to make the bottle better when it is lifted, stable and reliable.

The filling cylinder can be adjusted to accommodate bottles of different heights.

★aluminum capping machine

The number of capping heads is 6. Four caps are used to roll the aluminum caps, two of which are sealed by screws, and the other two are sealed by anti-theft ring. When the rolling pressure is too large, the spring is unloaded, which has the characteristics of not covering the cover and sealing tightly and reliably. . The capping head has a pre-cap function, which effectively corrects the bottle body and improves the sealing pass rate.

The tilting type pneumatic capper has the advantage of not damaging the cover. The 304 stainless steel lower cover groove has an electronic coverless detection system, which can automatically stop the lower cover without cover.

The capping head can be raised and lowered to accommodate bottles of different heights.

Transmission part

All the transmission gears are meshed with metal gears and oil nylon gears, which greatly reduces the noise and makes the whole machine transmission more stable.

★Control system and operator panel

Sealed electric control box, 304 stainless steel material, imported PLC, frequency converter, relay, photoelectric switch, induction switch relay component, touch screen operation panel, imported pneumatic components.

capacity: 4000-5000b/h(200ml,500ml)

Bottle diameter: Φ50~Φ92mm

Bottle height: 150-300mm

Main motor: 3.0KW

Filling method: micro-negative pressure gravity filling

Liquid inlet pressure 0.15~0.2 Mpa

Washing water consumption: 200Kg/h

Compressed air consumption : 0.6M3/min

Size(L*W*H): 2450*1850×2700(mm)

Weight: 2500Kg

By continuing to use the site you agree to our privacy policy.