Beverage / Isobaric / Beer Bottle Filling Machine

- Mobile: +86 15850399126

- Email: bella@jinrifillingmachine.com.cn

Beverage / Isobaric / Beer Bottle Filling Machine

BGF series beer filling machine has rinsing filling capping function combined in one machine. it suits for crown cap, pull ring cap, aluminum cap. it adopts advanced technologies of one time vacuum, two times vacuum, blowing foam structure, exhaust. it reduces the oxygen of beer bottle and make beer taste more better.

We have developed the latest BGF series glass bottle beer washing filling capping 3-in1 machine in accordance with the technological requirements for packaging beer in glass bottle by adopting advanced technologies both at home and abroad. Meanwhile, we are able to provide complete high-efficiency beer filling production line for the beer breweries.

With high precision mechanical filling valves. Our BGF Beer washing filling capping 3-in-1 unit stops vacuum when there are no bottles.

The BGF beer washing filling capping machine is equipped with external mechanical valve, inside which there is no spring or sealing element.

With high pressure frothing device, it is capable of double vacuum-pumping.

The BGF beer washing filling capping machine makes use of combined transmission stepless speed control, extending the speed modulating scope.

The machine has an automatic lubricating device so that the lubrication points can be automatically lubricated regularly in time. Our beer filling machine has high transmission efficiency, low noise and long lifetime.

In case of the blowout due to poor quality of the bottles during gas or beer filling, the filling valve will automatically close and the auto-cleaning device will work to treat the broken bottles.

With a full stainless steel magnetic hopper, the unscramble machine , feeding and discharging of crown caps are all performed by magnetic force. The caps are free from deforming, and can flow smoothly in large quantities during transmission,with the function of pre-covering which allows stable and reliable bottle transferring.

The capper has the function of automatic loading, which helps lower the bottle breakage.

For the centering guide of our BGF beer washing filling capping machine. We adopted double guide-bar mechanism, with the function of pre-covering which allows stable and reliable bottle transferring.

The movement of the wine jars and capping heads is driven by electricity in order to fit bottles of different size.

The material height in the tank is controlled by electric probe so as to ensure precise liquid level and reliable filling.

Model | BGF8-6-1 | BGF14-12-4 | BGF18-18-6 | BGF24-24-8 | BGF32-32-10 | BGF40-40-12 |

Capacity (BPH) | 500 | 1000 | 2000-2500 | 3000-4000 | 5000-6000 | 7000-8000 |

Filling method | Isobaric filling | |||||

Filling temperature ( ℃) | 0-4 | |||||

Bottle type | Glass bottle, bottle neck:θ50-90mm, bottle height:θ150-300mm | |||||

Main power (KW) | 0.37 | 2.2 | 3.0 | 4.0 | 5.0 | 5.5 |

Size (M) (L*W*H) | 1.8*1.4*2.65 | 2.2*1.9*2.75 | 2.6*2.1*2.75 | 2.7*2.2*2.75 | 4.1*2.4*2.75 | 4.2*3*2.8 |

Weight (KG) | 1500 | 2500 | 3500 | 5000 | 7500 | 9000 |

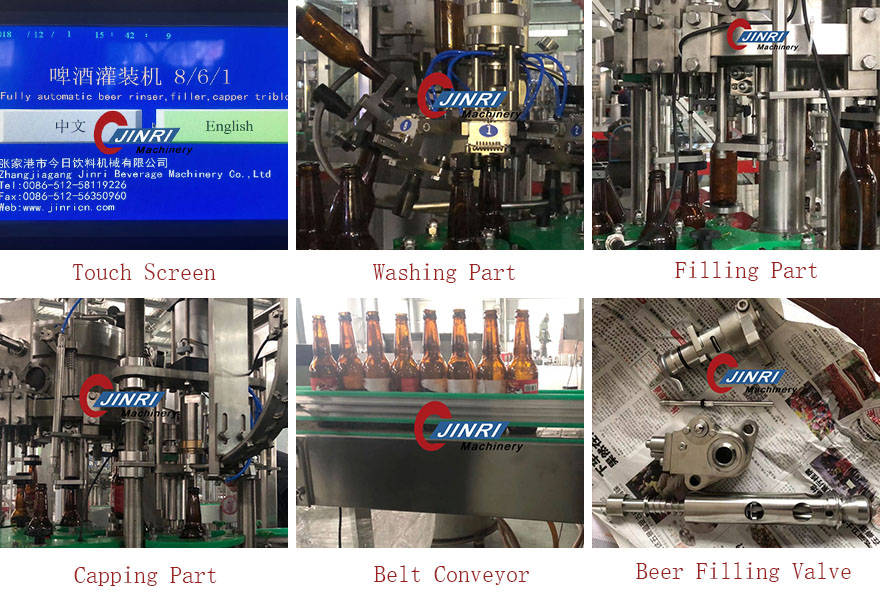

BGF8-6-1 Beer filling machine photo show:

After checking, we offer 12 months quality guarantee when machine arrived your factory. We provide free accessories. After you using our machine more than 1 year. We can provide lowest price accessories. Within 1 year, if you met some problem. You can email us firstly. If can not solve, we can provide engineer fly to your factory to check problem.

The first time, we will arrange our engineer go to buyer factory to install and train machine operations and maintenance.

We also provide the manual operation for you by email or together with our machine.But you need pay for our engineer tickets, visa, food, accommodation, salary 100usd per day per person.

By continuing to use the site you agree to our privacy policy.